|

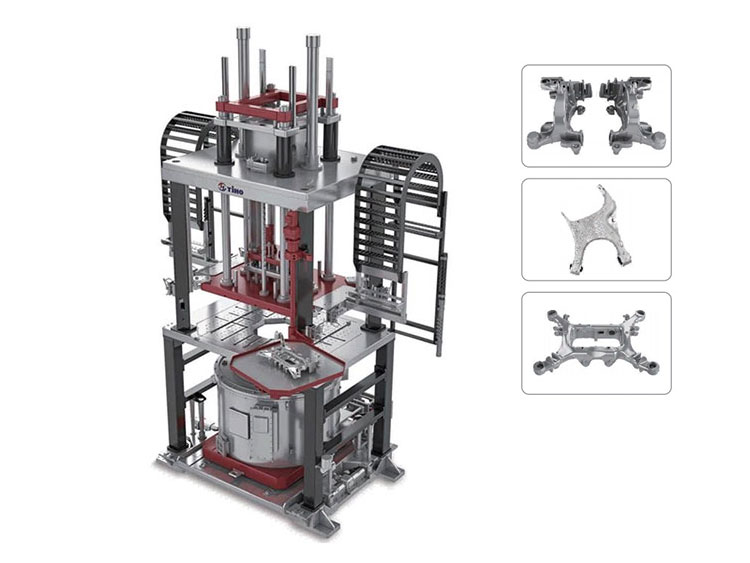

Model |

THDYJ-A24/18G2800 |

|

Mold Connection Specification |

Upper Column Spacing:2400*1800mm |

|

Opening and closing mold distance:800-2400mm |

|

|

Side core hydraulic circuit,top die 4 loops,bottom die 4 loops |

|

|

Upper mold moveable plate(length*width*thickness):2400*1800*150mm |

|

|

Holding Furnace Capacity |

2800kg |

|

Erter and Eit Moce of Hedding Fumace/Quantty of Fiser lbe |

Auminum water trolley transfer,holding furnace can nise and fall vertically and enter and exit back and forth/1-10 pcs (optional) |

|

Filling Contro |

PID method for high pression filling control with either proportional valve or digital valve block |

|

Mold Cooling |

1.Glass flowmeter 2.Digital flowmeter 3.Digital flowmeter+Proportionate valve control 4.1-96 cooling circuits (opti5o.nBarla)nd:SMC,KEYENCE,IFM,BURKERT |

|

Hydraulic System |

Adopt servo hydraulic drive,"Parker"servo vane pump,"PHASE"Servo Motor |

|

Electric System |

SIEMENS S7-1500+HM |

|

Pneumatic Element |

SMC |

|

Certificate |

Compliance with ISO mechanical IEC,electrical standards and CE certification |

|

Characteristic |

1.Fully automatic cycle 2.The robot can automatically put the filter screen and pick up the pieces 3.Accumulator maintains pressure and speeds up,reducing power consumption 4.The crucible furnace contains aluminum water for overall exchange,the aluminum water quality is better |