|

Mode |

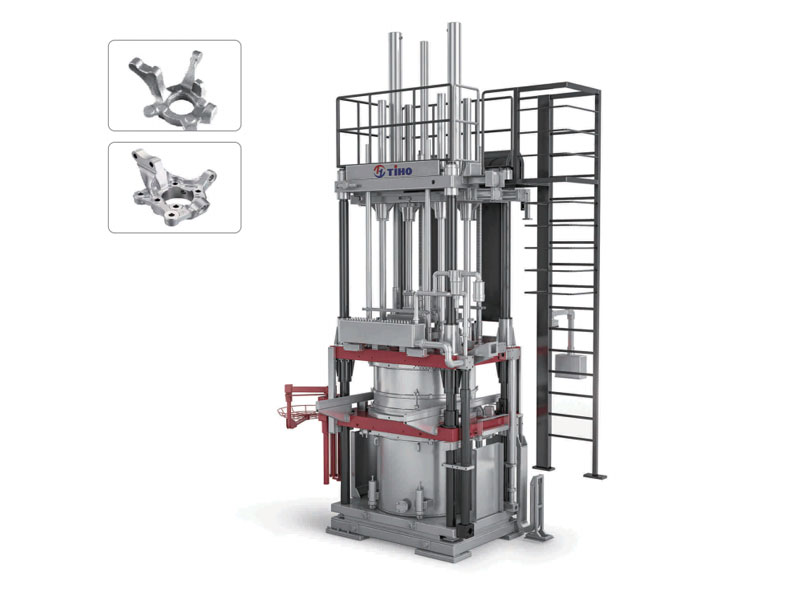

THCYJ-B18.2/11.6G900 |

|

|

Mold Connection Specification |

Upper Column Spacing:1820*1160mm |

|

|

Opening and closing mold distance:600-1900mm or800-2100mm |

||

|

Upper mold moveable plate(length*width*thickness):2260*1620*170mm |

||

|

ntermediate Plate(length*width*thickness):2260*1640*170mm |

||

|

Seal cover inner diameter:φ1450/016001φ2000mmm |

||

|

Holding Furnace Capacity |

Capacity of crucible holding furnace:650kg1800kg 1900kg |

|

|

Enter and Eit Mode ofHeking Furmecel Quanty ofRiser Ttbe |

The crucible holding furnace is pushed and pulled in and out by the aluminum water transfer vehiclel 1-8 pcs (optional |

|

|

Filling Contro |

PID method for high pression filling control with either proportional valve or digital valve block |

|

|

Mold Coolin |

1.Glass flowmeter 2.Digital flowmeter 3.Digital flowmeter+Proportionate valve contro 4.1-96 cooling circuits (optional) 5.Brand:SMC,KEYENCE,IFM,BURKERT |

|

|

Hydraulic System |

Adopt servo hydraulic drive,“Parker”servo vane pump,"PHASE"Servo Motor |

|

|

Electric System |

AB1769+HMI,Siemens 1500 Series |

|

|

Certificate |

Compliance with ISO mechanical IEC,electrical standards and CE certification |

|

|

Characteristic |

1.Fully automatic cycle 2.Optional full automaticrobot operation 3.Fast mold changeover device 4.The density and mechanical properties of castings can be improved by differential pressure casting |

|