|

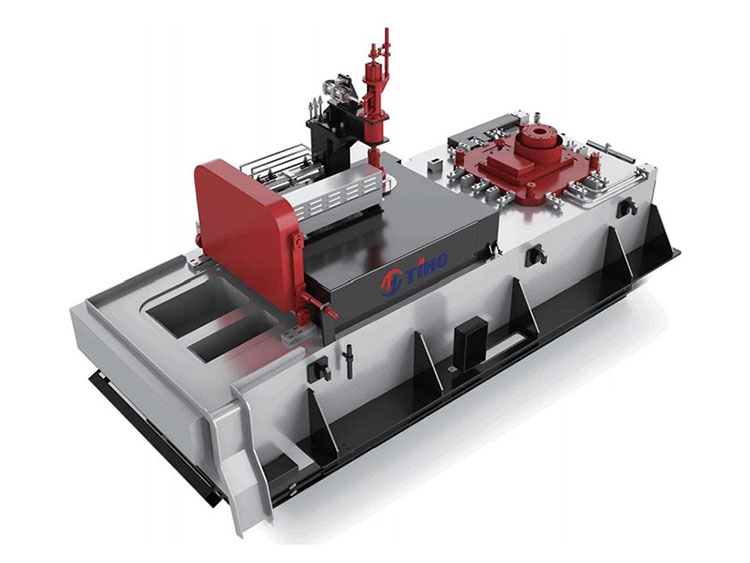

Model |

THBWL-B500/125 |

THBWL-B500125C |

|

Holding funace heating method |

mmersion heater,Stewing chamber Insert the furnacefromtopto bottom,Pressurizedchambers inserted intothefurnacechamberfromtheside wallofthefurnacebody |

|

|

Heating power of holdingfurnace |

Power of pressurized chamber;9kw*2=18kw(1siliconnitrideprotectivesleeve), Stewing chamber power:6kw*6=36kw(3silicon nitrideprotectivesleeves) |

|

|

Holding Furnace Capacity |

Pressurized Chamber 125kg,Stewing Chamber500kg |

Pressurized Chamber 250kg,Stewing Chamber 500kg |

|

Hoking furmace temperature measurement system |

Pressurized Chamber a set of aluminumliquid thermocouple,StewingChamberasetofaluminumiquid thermocouple,Each heater isequipped withathermocouple |

|

|

Liquid level detectionsystem forhaldingfurnace |

Pressurized Chamber a set of liquidleveldetection,Stewing Chamberasetofliquidleveldetection |

|

|

Energy consumptionduringinsulation |

Power consumption per houris25kwh±5% |

|

|

Hoking Fumace Iting method Quantity ofRiserTube |

4screwlifts overalllifting/1-4 pcs(optional) |

|

|

Enter And Exit Mode of Holding Furnace |

Cylinder in andout(strokeshouldnotexceed1800mm) |

Hydraulic motor access |

|

Pneumaticsystem |

SMC |

|

|

Pressure Contro |

PID method for high pression filling control with either proportionalvalveordigitalvalve block |

|

|

Hydraulic System |

Borrow the hydraulicsystemof LPDC |

|

|

Electric System |

Siemens S7-1500+human-computer interaction interface,linked with LPDC electricalcontrolsystem |

|

|

Characteristic |

1.Holding furnace can be combined with LPDC for continuous pressurecasting,andtheaveragedailyoutputisincreased by10%-20% 2.Aluminum liquid was placed in a stew chamber,andthetemperaturewasmaintainedat700℃±1.Theimpuritiesin liquid aluminum precipitate in thestew room,andthequalityofliquidaluminumandcastingisimproved. 3.Pressure chamber and stew chamber,the cavityspaceis reduced,energyconsumptionis reduced,andtheeaction between liquid aluminumandairisreduced 4.Use ofimmersion heaters,liquidlevel oxides reduced alot,thermalefficiencyofmorethan80%. |

|