|

Model |

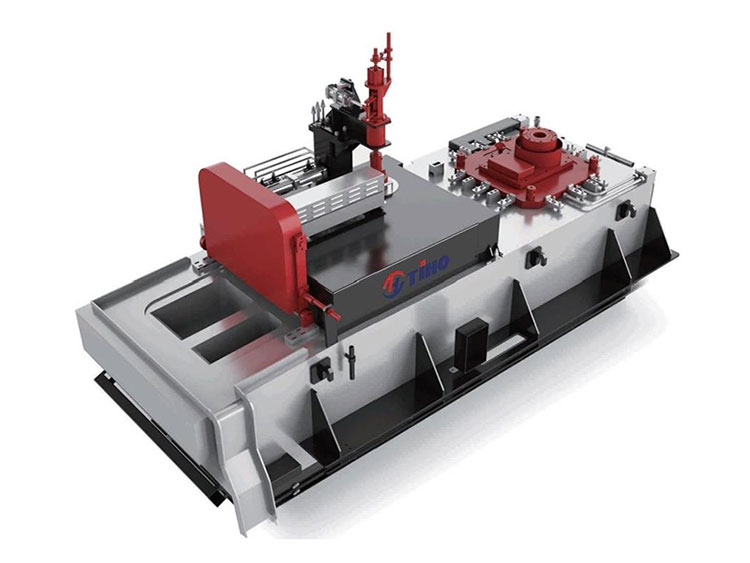

THBWL-B500/125 |

THBWL-B500/250 |

|

Holding furnace heating method |

Immersion heater,Stewing chamber Insert thefurnace from top to bottom,Pressurized chamber is inserted into the furnace chamber from the side wall of the furnace body |

|

|

Heating power of holding furnace |

Power of pressurized chamber:9kw*2=18kw(1 silicon nitride protective sleeve) Stewing chamber power:6kw*6=36kw (3 silicon nitride protective sleeves) |

|

|

Holding Furnace Capacity |

Pressurized Chamber 125kg,Stewing Chamber 500kg |

Pressurized Chamber 250kg,Stewing Chamber 500kg |

|

Hoking furmace temperature measurement system |

Pressurized Chamber a set of aluminum liquid thermocouple,Stewing Chamber a set of aluminum iquid thermocouple,Each heater is equipped with a thermocouple |

|

|

Liquid level detection system for halding furnace |

Pressurized Chamber a set ofliquid level detection,Stewing Chamber a set of liquid level detection |

|

|

Energy consumptionduring insulation |

Power consumption per hour is 25kwh±5% |

|

|

Holding fumece lfing methodi Quantity of Riser Tube |

4 screw lifts overall lifting/1-4 pcs (optional) |

|

|

Enter And Exit Mode of Holding Furnace |

Cylinder in and out |

Hydraulic motor access |

|

Pneumatic system |

SMC |

|

|

Filling Contro |

PID method for high pression filling control with either proportional valve or digital valve block |

|

|

Hydraulic System |

Borrow the hydraulic system of LPDC |

|

|

Electric System |

Siemens S7-1500+human-computer interaction interface,linked with LPDC electrical control system |

|

|

Characteristic |

1.Holding furnace can be combined with LPDC for continuous pressure casting,and the average daily output is increased by 10%-20% 2.Aluminum liquid was placed in a stew chamber,and the temperature was maintained at 700℃±1.The impurities in liquid aluminum precipitate in the stew room,and the quality of liquid aluminum and casting is improved. 3.Pressure chamber and stew chamber,the cavity space is reduced,energy consumption is reduced,and the reaction between liquid aluminum and air is reduced. 4.Use of immersion heaters,liquid level oxides reduced a lot,thermal efficiency of more than 80%. |

|