|

Mode |

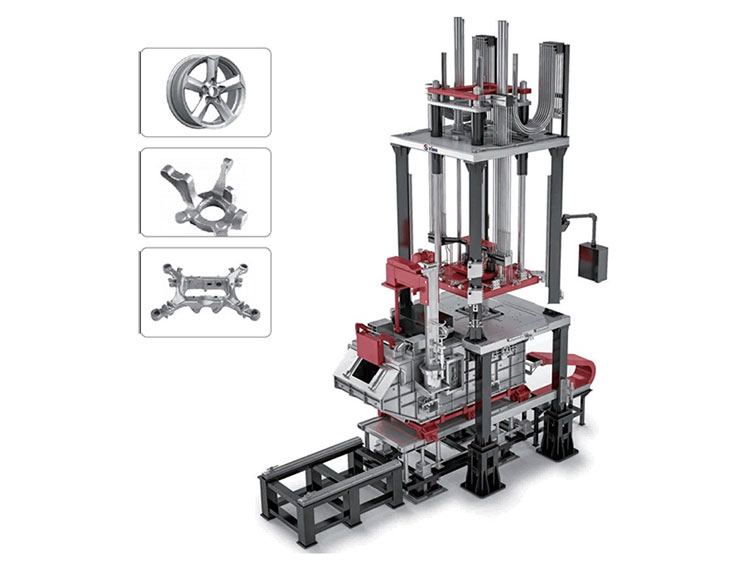

THDYJ-A16/14-B700/400 |

THDYJ-A19/15-B700/400 |

THDYJ-A21/16-B740/650 |

|

|

Mold Connection Specification |

Upper Column Spacing |

1600*1470mm |

1900*1570mm |

2100*1600mm |

|

Cpening and cbsngmoll distance |

565-2065mm |

565-2065mm |

580-1980mm |

|

|

Side Core Cylinder |

Optiona |

|||

|

Upper mold moveable plate length*width*thickness) |

1150*1050*120mm |

1600*1440*120mm |

1600*1440*120mm |

|

|

Holding Furnace Capacity (Effective capacity) |

Fressuriced Chamber 40Ckg,Stewing Chamber 700g |

ressunzed Chamber 400kg,Stewing Cnamber 700kg |

Pressurzed Chamber 65Ckg Stewng Chamber 74Ck |

|

|

Emter and Eit Mooe of Hoking Fumace Quntity af Riser Tube |

Holding funace can rise and fall vertically and enter and exit back and forth/1-8 pcs (optional ) |

|||

|

Filling Contro |

PID method for high pression filling control with either proportional valve or digital valve block |

|||

|

Mold Cooling |

1.Glass flowmeter 2.Digital flowmeter 3.Digital flowmeter+Proportionate valve contro 4.1-96 cooling circuits (optional) 5.Brand:SMC,KEYENCE,IFM,BURKERT |

|||

|

Hydraulic System |

Adopt servo hydraulic drive,"Parker"servo vane pump,"PHASE"Servo Motor |

|||

|

Electric System |

SIEMENS S7-1500+HMI |

|||

|

Certificate |

Compliance with ISO mechanical IEC,electrical standards and CE certification |

|||

|

Characteristic |

1.Fully automatic cycle 2.Optional full automatic robot operation 3.Automatic fast mold changeover device 4.Riser tube number is variable 5.Continuous production,thecapacity increase 15%-20% |

|||