|

Mode |

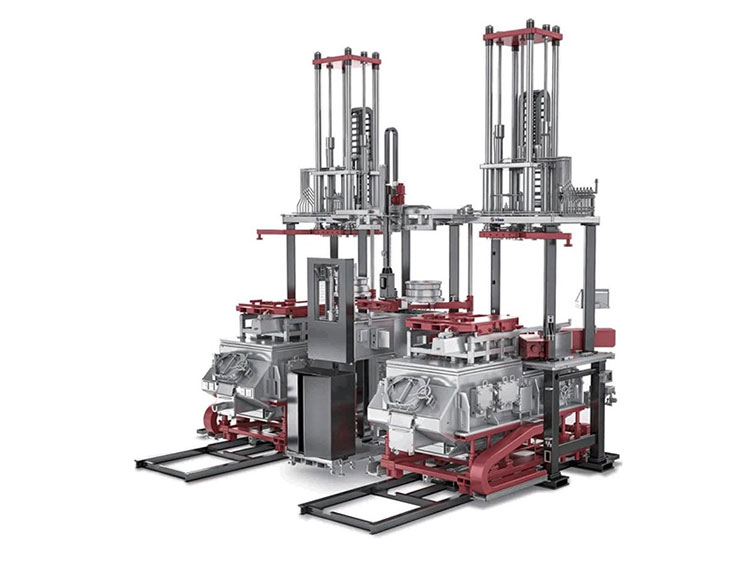

THDYJ-A20/20-B900/600 |

|

Mold Connection Specification |

Upper Column Spacing:2000mm*2000mm |

|

Opening and closing mold distance:750mm-2850mm |

|

|

Side Core Cylinder:Optiona |

|

|

Upper mold moveable plate(length*width*thickness):2000mm*2000mm*150mm |

|

|

Holding Furnace Capacity |

Pressurized Chamber 600kg,Stewing Chamber 900kg |

|

Ente And Est Mcoe of Hcking FureceQartty af Piser Tihe |

Holding funace can rise and fall vertically andenterandexitbackandforth./1-8pcs(optional) |

|

Filling Control |

PID method for high pression filling control with either proportional valveordigitalvalveblock |

|

Moldcooling |

1.Glassflowmeter,2.Digitalflowmeter,3.Digitalflowmeter+Proportionate valvecontrol,4.1-96 cooling circuits(optional),5.Brand offlowmeter:SMC,KEYENCE,IFM,BURKERT |

|

Hydraulic System |

Adopt servo hydraulic drive,"Parker"servo vane pump,"PHASE"Servo Motor |

|

Electric System |

SIEMENS S7-1500+HM |

|

Certificate |

Compliance with ISO mechanical IEC,electrical standardsandCEcertification |

|

Characteristic |

1.Fully automaticcycle 2.Optional full automaticrobotoperation 3.Automatic fast moldchangeoverdevice 4.Riser tube numberisvariable 5.Continuous production,the capacity increase159%-20% |